Exothermic welding mold and types

- Post author:armaghan kia

- Post published:January 31, 2024

- Post category:Exothermic Welding

- Post comments:0 Comments

Exothermic welding mold and types

Exothermic welding mold, also known as exothermic welding crucible or mold, is a device used in the exothermic welding process to create a permanent and strong electrical connection between two or more metal components. Exothermic welding, also called thermite welding, is a method of joining metals using a chemical reaction that produces molten metal and allows it to flow into the joint between the components.

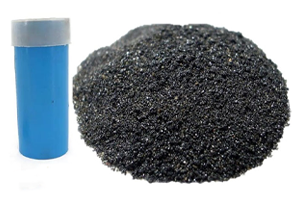

The exothermic welding mold typically consists of a refractory mold, a crucible, and a starter. The refractory mold is designed to shape and contain the molten metal during the welding process. The crucible holds the exothermic welding mixture, which usually includes powdered metals such as aluminum and iron oxide, along with other components to initiate the exothermic reaction. The starter is a combustible material or ignition source that initiates the reaction when ignited.

Types of exothermic welding molds include:

1.Graphite Molds:

These molds are made of graphite and are known for their durability and ability to withstand high temperatures. Graphite molds are commonly used for various exothermic welding applications.

2.Ceramic Molds:

Some exothermic welding molds are made of ceramic materials. Ceramic molds offer good resistance to high temperatures and provide a reliable option for certain welding applications.

3.Steel Molds:

In some cases, steel molds may be used for exothermic welding. These molds are durable and can withstand the high temperatures generated during the exothermic welding process.

The selection of the mold type depends on the specific application, the metals being joined, and the desired characteristics of the weld. Exothermic welding is often used for grounding applications, bonding copper conductors, and creating reliable electrical connections in various industries.